A Paradigm Shift in Airport Logistics

A Better Way to Manage Deliveries at Airports

Contributors: Clint Laaser, L.J. Marciano and Richard Barone with Steve Wareham

As many of our readers are aware, airports are complicated facilities that rely on a constant supply of a multitude of goods to operate. On a daily basis, there are deliveries of food, paper products, apparel, electronics, mechanical parts, and countless other items to meet the demand of the restaurants, hotels, concession outlets, airline club lounges, and airport and aircraft maintenance staff at the airport. The safe and efficient processing and movement of these goods is paramount to an airport’s performance and its ability to serve customers. Yet, at most airports today, this process is fragmented and inefficient, resulting in higher operating costs and negative impacts on roadways surrounding the landside and airside.

At its core, an airport is a collection of buildings surrounded by pavement – roadways, aprons, taxiways and runways. Like most commercial businesses, these buildings typically receive deliveries directly from the shipper. In some cases, trucks or vans are routed to loading docks on the landside, but in many cases shippers are required to clear security and enter the airside roadway network to make their deliveries directly to terminals and other airside facilities. This process costs shippers time which is then passed on to the customer. It also impacts the airports, who are forced to manage the process to provide shippers with security clearance and to check vehicles for possible hazardous materials. This also puts commercial traffic on busy airport ramps which foremost is a safety concern, but also drives expenses related to damage and delays.

Source: PARAS 0024 Study – CRDC; National Safe Skies Alliance; Miller Dunwiddie; Landrum & Brown

With the adoption of just-in-time inventories, most facilities no longer carry substantial inventory. Storage space for warehouse goods is costly, while the value of those goods depreciates as they sit in storage. Therefore, shippers are more concerned with delivering goods on-time than ensuring their vehicles are full, resulting in even more trips. Partially filled trucks combined with numerous shippers creates congestion on the landside and airside. Access to airside, in particular, is problematic as volumes and the number of trips increase.

Queuing is a safety issue at security checkpoints and trucks can interfere with other ground service equipment and even aircraft if they must cross taxiways to reach their destination. This queuing also impacts the environmental footprint of an airport as trucks idle their engines or otherwise wait for delivery space adding unnecessary vehicle emissions to the airport.

There is a much more efficient and cost effective way to manage deliveries at an airport, which is to construct a Consolidate Receiving and Distribution Center (CRDC). This facility can reduce the number of trucks by making sure they are full (or fuller) when they arrive to the airport and decrease the number of shippers to the airside to just one. The following sections will overview the elements of a CRDC and how they benefit airports.

Consolidated Receiving and Distribution Center (CRDC) Facilities

Consolidating deliveries for more efficient distribution is not a new concept, but its application at airports is. CRDC facilities operate very similar to airport cargo or warehouse facilities. The main function is to efficiently process the goods, which includes consolidation and storage as well. An early CRDC was constructed at the Detroit Metropolitan Wayne County Airport (DTW) in 2001 as part of the new McNamara Terminal. The idea was straightforward; limit the number of trucks that has airfield access and attempt to consolidate as many landside vehicle trips as possible to the airport. The airport would have an on-site distribution center where all goods would be received, screened, and logistically organized for delivery to node points in the terminals. These goods would then be cross docked and consolidated onto smaller trucks – filling these trucks in the process and eliminating most partial loads, reducing the number of truck trips to the airport by about two-thirds as well as pushing these deliveries to more non-operating early morning hours.

The benefits of a CRDC fall into four categories – safety and security, operations, financial and environmental. The table below outlines the specific benefits for each.

| Benefits of a CRDC | |

|---|---|

|

Safety and Security |

|

|

Operations |

|

|

Financial |

|

|

Environmental |

|

CRDC Locations & Building Types

L&B has documented over 20 CRDCs that have been implemented over the past two decades. Our study looked at examples globally with a focus on facilities in the United States. There are many variables that should be studied to determine the appropriate approach that aligns with each airport’s unique constraints. In addition, there are many CRDC facilities currently in planning or design/construction that will be implemented in the near future.

CRDC Locations

Determination of a preferred location that minimizes travel times (for both concession vendors and the CRDC operator) to the terminal/concourse nodes is critical. The main purpose of the facility is to provide a more efficient and consolidated pathway for goods to and from the vendor warehouses to the terminal secure nodes. As such, the facility must provide the proper security screening to access the AOA for secure delivery. Three location types have been identified and documented in accomplishing these goals:

| AOA Fence Adjacent | Remote Facility | Airport Loading Dock | |

|---|---|---|---|

| Percentage of 20 Airports Studied | 45% | 35% | 20% |

| Select Airport Location Examples | SLC, PDX, SAN | LGA, YYZ, LHR | BWI, DTW, PIT |

Ideally, the location of the CRDC is determined within the Airport Master Plan process. It is often assigned by geographic or topographic constraints that do not allow a proper location on the AOA fence line due to other functions that require highest and best use for those locations. A remote facility can process goods in the same secure process and just as efficiently as AOA fence locations by utilizing CRDC vendor trucks that are geofenced with Radio Frequency Identification (RFID) tracking to ensure proper security process. Traffic congestion could impact delivery times, and it should be further studied when deciding on the development of a remote CRDC location.

Building Types – New Construction vs. Retrofit/Renovation

While a newly constructed building offers an ideal layout based on an airport’s needs, often times, a CRDC can be developed by renovating an existing underutilized warehouse facility. This allows for an expedited and more cost-efficient solution.

Of the 20 airports benchmarked, only 25 percent of the CRDC locations, including SAN, SLC and MSP, utilized a newly constructed building. The remaining 75 percent were repurposed existing facilities, including CRDCs at AUS, BOS and LHR, amongst others.

Tampa International Airport (TPA)

Salt Lake City International Airport (SLC)

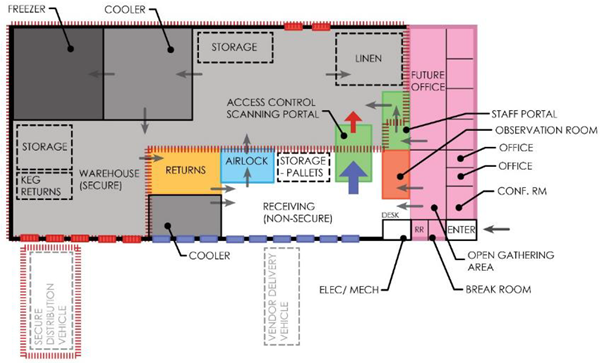

Typical CRDC Program Components

The building layout for a CRDC follows a prototypical process or diagram that include five (5) main components.

| CRDC Program Components | |

|---|---|

|

Administration |

|

|

Inbound/Receiving |

|

|

Security/Screening |

|

|

Outbound/Returns |

|

|

Support Spaces |

|

In addition, there are many other uses that have synergies to CRDC operations that should be considered while planning for this building type. The recently published Program for Applied Research in Airport Security (PARAS) 0024 National Safe Skies Alliance Study on CRDC’s provides more information on these uses along with an in-depth tutorial and further benchmarking for CRDC implementation.

Potential Financing Options for CRDC Implementation

In the United States, the funding and financing of a CRDC is the responsibility of an airport and is not considered a capital project eligible for funding through Passenger Facility Charges (PFC), the FAA or state grants. In other jurisdictions the funding arrangements will also generally fall to the airport. The five broad options that Airports have used to fund the construction of a CRDC include:

- Use of airport funds on hand

- General airport revenue bonds (GARB)

- Special facility bonds

- Private developer (Public Private Partnership or concession model)

- General capital investment funds

In some cases, a CRDC is included as part of a larger capital project such as the construction or expansion of a new terminal. In other examples, it is a stand-alone project possibly connected to a concessions program upgrade. Each approach may dictate the appropriate way to seek capital to finance the project. A model will also need to be developed to address the operations and maintenance costs of the CRDC.

Airport Implementation Considerations

Airports should be cognizant of the following six (6) considerations when undertaking a planning process for a CRDC:

- Create an oversight group (decision makers) and a stakeholder group

This enables effective stakeholder input (concessions, security, airside, landside, facilities, environment, resilience, recycling, other tenants) to be considered in the early planning stages for a CRDC.

- Identify potential cost savings that will result from a CRDC implementation

Use this for airport review in identifying effective cost structures.

- Explore unique alternatives for additional program items that have synergies

For example, CRDC second floor, common use commercial kitchen, grease handling, food shelf support, etc.

- Examine monetizing CRDC services to lower annual O & M costs

For example, adding a common use commissary, retail storage on a second level, etc.

- Bring a CRDC Operator on board prior to specification and design

Enable better requirement specification and encourage reduction in change orders and/or later costs at facility commissioning.

- Consider tangential benefits

For example, the TSA has a growing focus on insider threats. They are aware of the benefits in security that a CRDC brings including screening of goods, fewer individuals with secure and sterile access, etc.

The need for a CRDC is best defined through a structured planning process that involves a facility analysis, comprehensive stakeholder engagement and a structured programming process to help determine an airport’s unique CRDC needs. A “Needs Evaluation” team should have expertise in, but not limited to, airport operations, airport security, concessions, and financing. This programming effort can assist airports in utilizing the best financial or implementation means to provide both the capital for CRDC construction, as well as benchmarked alternatives for the best approaches to covering annual O&M costs.

L&B has assisted large, medium and small hub airports across the country with strategic planning for implementation of CRDC facilities. Please contact

L.J. Marciano to schedule an introductory tutorial for your leadership and stakeholders and/or to discuss this issue further.

What is the L&B LAB?

The LAB is Landrum & Brown’s research and development unit. Our mission is to harness decades worth of industry knowledge and expertise to develop innovative solutions that support our clients along with promoting industry thought leadership.

This document was prepared by Landrum & Brown, Inc. | Richard.Barone@landrumbrown.com

Sign up to receive our next L&B LAB in your inbox!